Electrical Cord Hazards: Looking Into Outlet Alternatives

Extension cords (cord sets), cables, and electrical cords are types of flexible cords. Flexible cords and cables are used to connect electrical equipment to a power source. When not used properly, electrical cord hazards develop, making extension cord safety in the workplace important.

Mitigate electrical cord hazards in the Minnesota workplace with this information from the OECS safety consultants. You can also learn more about OSHA’s regulations regarding extensions cords by visiting our OSHA compliance checklist.

Electrical Cord Hazards in the Workplace: Common Scenarios

- The office doors do not seal well, allowing cold air to leak in. Bottom line: the office is cold. You need the portable heater placed under your desk and set on high to survive the day. You need to route an extension cord for the space heater under your cubicle and down the aisle to the outlet located at the end of the hallway.

- In production, you need to move the floor-mounted drill press to a different location. Wouldn’t you know it? No outlet is near where the press is placed! You need to get a 50-foot extension cord.

- The company set up a cubicle in shipping and receiving, and installed a computer terminal/printer to use to track shipments and deliveries. Of course, the outlet is on the other side of the cubicle. You drill a hole into the panel that is next to the wall to route the power strip cord through the hole to plug it into the receptacle.

Farfetched scenarios? Not really. Our health and safety consultants see situations like this all the time. Every situation like this requires a strategic approach to extension cord safety in the workplace.

An extension cord is a potential fire ignition hazard, electric shock hazard, and trip/slip/fall hazard (or worse). What are some facts you should know about extension cord use and limitations to avoid these hazards and likely OSHA fines?

Temporary Wiring:In the workplace, extension cords are not designed to be used as fixed wiring. This means extension cords are temporary. When you are finished with your task, the extension cords should be unplugged from the equipment or tool, removed from the outlet, wrapped and placed in safe storage.

What happens if the extension cord is left in place as seen in scenario #2 above?

To maximize extension cord safety in the workplace, the extension cord should be removed, because the wiring can break down and become a hazard. From a practical standpoint, if equipment has been placed in an area with no outlets, you will need an extension cord until permanent wiring can be installed. If the equipment will be there for an extended time, permanent wiring should be installed. A general rule of thumb: if the equipment will be in place for more than 30 days, a permanent type of wiring should be installed.

OSHA regulations do permit Christmas decorative lighting and similar set-ups relating to lighting used for specific and temporary purposes for a period not to exceed 90 days to help minimize electrical cord hazards in the workplace.

Fire ignition Source:

Extension cords with thick copper wire can carry more electricity. Thinner copper wire will not be able to carry a heavier load. This is just like how a water pipe with a large diameter carries more water than pipes with smaller diameters. As a result, the thinner wire will begin to heat up due to the friction caused by electricity load trying to power the device. Going back to the pipe analogy, consider a pump moving water at 100 PSI through a large diameter pipe. If you substituted in a smaller pipe, but tried to pump the same amount of water, the smaller pipe will deal with more pressure build up.

Overheated wire can melt the insulation and expose the wires to paper, cardboard, and other potential causes for a fire. Additionally, if the cord is a fairly long distance, it can lose power as well, causing even more potential electrical hazards in the workplace. If you notice an extension cord smoking, it’s time to unplug it from the outlet and reassess how you are using this type of equipment.

Overheated wire can melt the insulation and expose the wires to paper, cardboard, and other potential causes for a fire. Additionally, if the cord is a fairly long distance, it can lose power as well, causing even more potential electrical hazards in the workplace. If you notice an extension cord smoking, it’s time to unplug it from the outlet and reassess how you are using this type of equipment.

This ribbon extension cord is used around the home to plug in such devices as lamps, clocks, and other light-duty electrical devices up to 7 amps. An under-the-desk, smaller space heater will use around 12.5 amps. The ribbon extension cord is only rated for 7 amps, however; anything more will result in the cord being overheated. A ribbon extension cord cannot be used in commercial or industrial type settings.

When using an extension cord, check the amps required to power the needed device, equipment, or tool against the extension cord’s rating. Select the correct gauge wire and cord length to meet the electrical demands. See the gauge cord section chart used by our safety company at the end of this article.

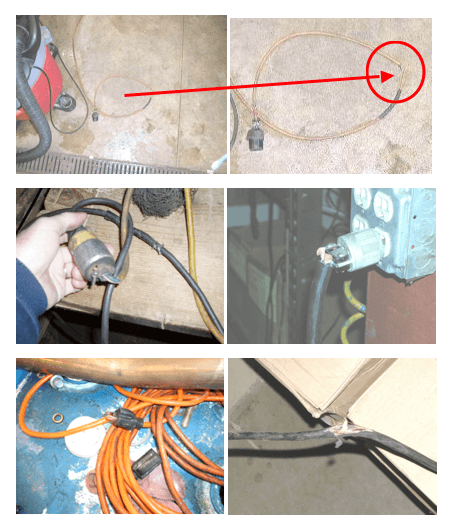

Damaged Extension Cords: Avoid placing cords around sharp corners, through windows or doorways, or in other pinch points. A defective or damaged cord can cause a fire from electrical resistance in the wire. The heat buildup will melt the cord, exposing conductors to combustibles in the work area. Remember, cord damage may not be visible. When in doubt, put workplace safety first and use an undamaged, properly rated cord.

Inspect Cords for Damage: Before use, inspect the cord to make sure the outer insulation is intact. Look to see if the ground pin is attached. Ensure the cord’s outer insulation is not broken at the plug end or the insert end. Often the cord has been broken, exposing the conductors. Check to see if the cord is capable of the “load” that the equipment will require by looking at the cord gauge chart at the end of this article.

Substitute for Fixed Wiring: Flexible cords like extension cords cannot be used as a substitute for fixed wiring, or run through holes in walls, ceilings or floors. They cannot be attached to building surfaces or concealed behind building walls, ceilings or floors.

Fire-Rated Doors Obstructed: A fire-rated door is a bulwark, a defensive wall, to prevent fire spread. A fire-rated door that cannot close properly due to a cord in the entrance negates the door’s purpose and could let a fire spread to adjacent areas.

Surge Protectors (Power Strips): Extension cords must be plugged directly into wall outlets to minimize electrical cord hazards in the workplace. Do not “daisy chain” – that is, plug extension cords into surge protectors or other extension cords.

Wet Hands: Do not plug an extension cord into an electric outlet with wet hands, or if either end of the plug is wet! Do not come in contact with or use any electrical items while standing in water.

Slips, trips and falls amount to more than 20 percent of all job-related injuries and are a significant cause for back injuries. According to Federal OSHA information, approximately 15 percent of all accidental deaths in the U.S. annually are from unintentional falls. Additionally, 12 to 15 percent of workers’ compensation claim expenses are from slips, trips and falls. Extension cords across walkways, aisles, and work areas contribute to this statistic. Be careful and follow our extension cord safety tips in the workplace.

If you have questions, need information about specific scenarios, or generally want to know more about occupational health and safety, contact our workplace safety company. We offer:

- Safety consultant services

- Hazard identification and risk assessments

- Comprehensive safety audits

- OSHA assistance

- On-site training

Let OECS Help With Extension Cord Safety in the Minnesota Workplace

To ensure extension cord safety and minimize electrical cord hazards in the workplace, request a cord safety assessment by contacting our Minnesota-based workplace safety team.

Cord Gauge Chart

| Cord Length | Device Amperage Rating | Good for Use with | Minimum Wire Gauge |

|---|---|---|---|

| 25 Feet | 1 – 13 Amps |

| 16 Gauge - (Light Duty) |

| 25 Feet | 14 – 15 Amps |

| 14 Gauge - (Medium Duty) |

| 25 Feet | 16 – 20 Amps |

| 12 Gauge - (Heavy Duty) 10 Gauge - (Extra Heavy Duty) |

| 50 Feet | 1 – 13 Amps |

| 16 Gauge - (Light Duty) |

| 50 Feet | 14 – 15 Amps |

| 14 Gauge - (Medium Duty) |

| 50 Feet | 16 – 20 Amps |

| 12 Gauge - (Heavy Duty) 10 Gauge - (Extra Heavy Duty) |

| 100 Feet | 1 – 10 Amps |

| 16 Gauge - (Light Duty) |

| 100 Feet | 11 – 13 Amps |

| 14 Gauge - (Medium Duty) |

| 100 Feet | 14 – 15 Amps |

| 12 Gauge - (Heavy Duty) |

| 100 Feet | 16 – 20 Amps |

| 10 Gauge - (Extra Heavy Duty) |

| 150 Feet | 1 – 7 Amps |

| 14 Gauge - (Medium Duty) |

| 150 Feet | 8 – 10 Amps |

| 12 Gauge - (Heavy Duty) |

| 50 Feet | 11 – 15 Amps |

| 10 Gauge - (Extra Heavy Duty) |

763.417.9599

763.417.9599